Project Video Link

Automation has been playing a major role in manufacturing such as in automotive, electronics, and pharmaceutical industries. While robots are able to perform repeatable tasks with speed and accuracy, its use in garment industry has been limited by challenges in grasping and handling soft fabrics using commercially available robot end effectors. This paper considers a common garment manufacturing process, fabric fusing, which combines a piece of woven or knitted fabric with an interface material to provide additional firmness and support. Current practice uses human operators to perform fabric pick-up, alignment, and manipulation tasks to feed the combined materials into a fusing machine.

Robotic Assistant for Repurposable Fabric Fusing Operations

ARM Institute

Glenn Saunders

John T. Wen

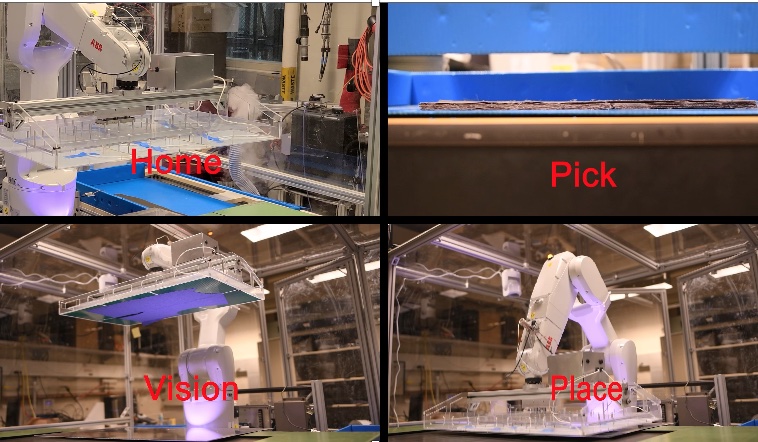

In this project we developed a robotic system with an electroadhesion robot gripper containing actuated pins to alleviate human operators from performing these repeated and laborious tasks in an uncomfortable manufacturing environment. This robotic system can reliably pick-up fabric pieces, place them without wrinkles, align them using machine vision, and feed the combined bundle through the conveyor belt into the fusing machine. The actuated pins interlaced with the electrodes on the gripper can detach the fabric from the gripper with residual charges and to slide the bundle onto the conveyor belt without affecting the fabric alignment. The electroadhesion force depends on the applied voltage, fabric material property, and humidity. The environmental condition needs to be controlled and the applied voltage adjusted based on the type of fabric materials and humidity to achieve reliable performance. The prototype system has been demonstrated in both the laboratory setting and actual garment manufacturing shop floor.