Multi-proble microassembly based on vision and force feedback

Our motion control research is motivated by high speed and high precision requirement in electronic manufacturing. We have investigated following approaches:

- High speed trajectory tracking: we use a combination of feedback and feedforward (learning-based) control to achieve high performance trajectory tracking.

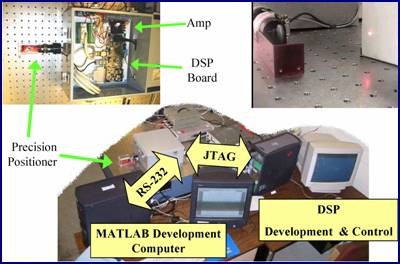

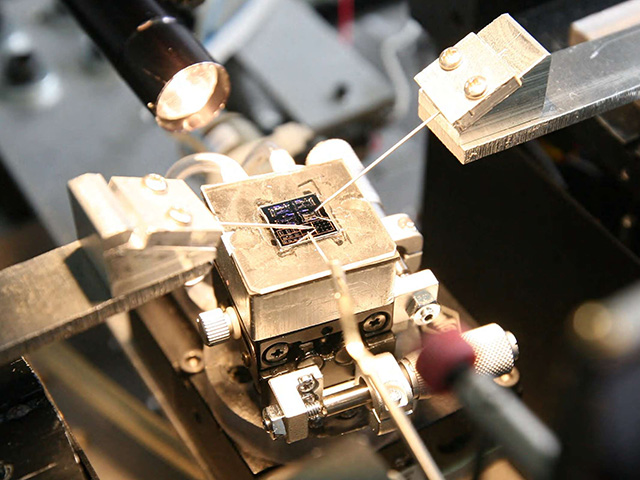

- Motion and force control: we use multi-camera feedback to coordinate two probes to manipulate sub-mm parts (using vision-based force control to maintain grasp stability).

- Motion planning: To process multiple features in electronic manufacturing, the problem becomes a motorized traveling salesman problem. We have developed efficient suboptimal algorithms to generate practical solutions.