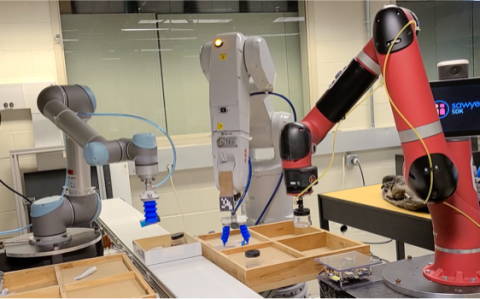

This project focuses on human-robot teaming for handling, placing, and conforming tasks. It combines control technologies and task planning, allowing a human-robot team to better manipulate large composite sheets. The process involves lifting, transporting, and completing the conforming process with the human-robot team interacting in an intuitive way to accomplish complex manufacturing tasks.

Completed Projects

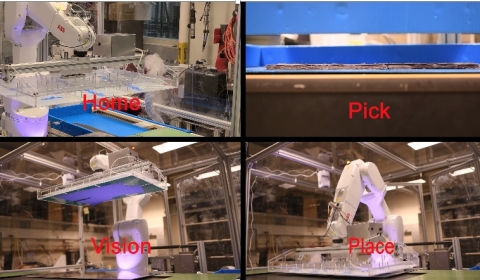

In this project we developed a robotic system with an electroadhesion robot gripper containing actuated pins to alleviate human operators from performing these repeated and laborious tasks in an uncomfortable manufacturing environment. This robotic system can reliably pick-up fabric pieces, place them without wrinkles, align them using machine vision, and feed the combined bundle through the conveyor belt into the fusing machine.

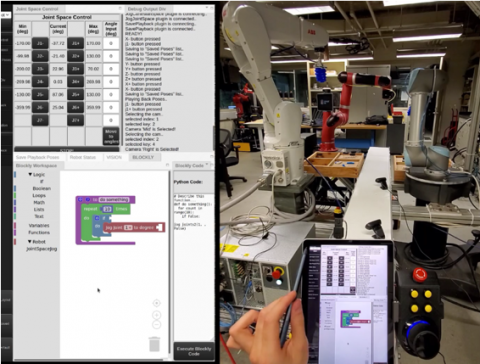

Teach pendant is the most common method to operate, control, and program industrial robots today. Despite its prevalence, current teach pendants for industrial robots are vendor specific and do not usually work with additional sensor inputs such as machine vision and force/torque sensors. There are now widely available open-source robotics software performing complex tasks, ranging from motion planning to sensor guided motion. Unfortunately, these capabilities are not readily incorporated into teach pendant operations, unless the robot vendor chooses to take the initiative.

This project aims to bridge a major gap in the current state of industrial robots: easy, rapid, and secure integration of robots, sensors, peripherals, and simulation software from multiple vendors and platforms. Our approach is based on Robot Raconteur (RR) which is an advanced augmented object-oriented middleware technology specifically designed to provide true plug-and-play interoperability capabilities for automation/robotics systems. The objective of this project is to increase the RR Technology Readiness Level to bring it from research environment to industrial usage.

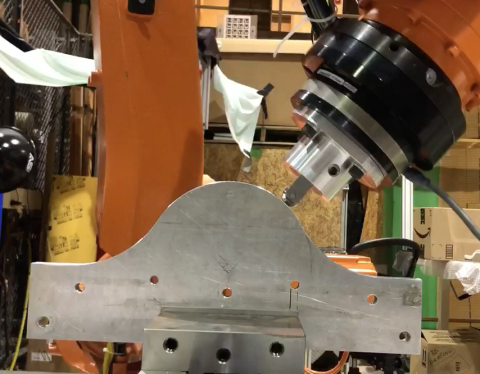

Surface treatment processes, including burnishing, deep rolling, shot peening, laser shock peening, and ultrasonic peening are commonly utilized to improve performance of a wide variety of commercial and aerospace products. Of all these methods, the deep rolling process is of interest because it can be customized according to part geometry and the required compressive residual stress profile that will enhance part fatigue life. Due to the system rigidity, conventional machining/CNC platforms are utilized in current practice. The CNC systems are typically expensive with low throughput.