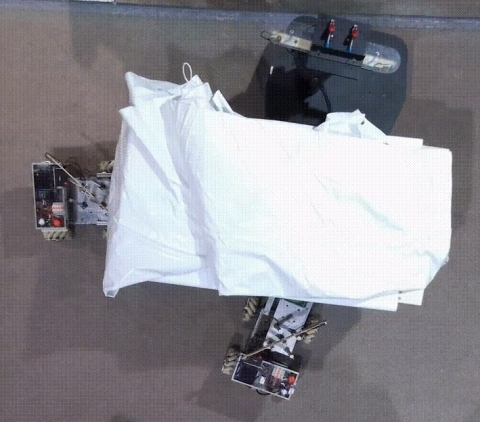

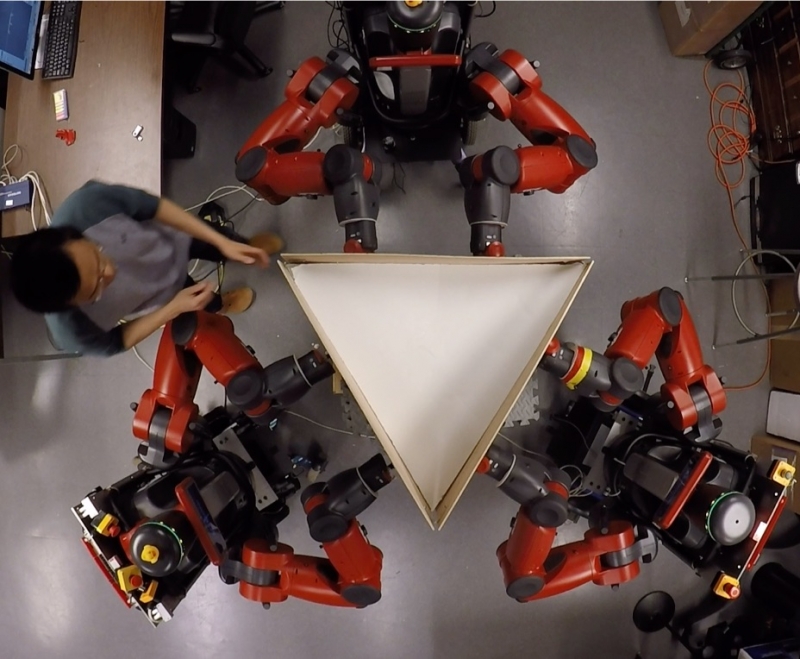

Three Baxter Robots collaboratively holding a box with force control and move under the human guidance

Our robotic research has three main motivations:

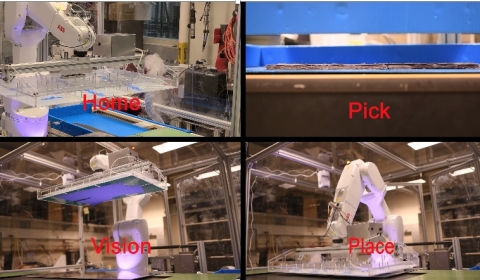

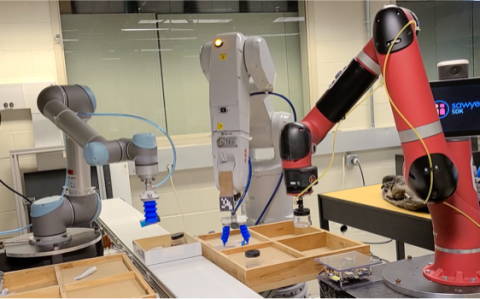

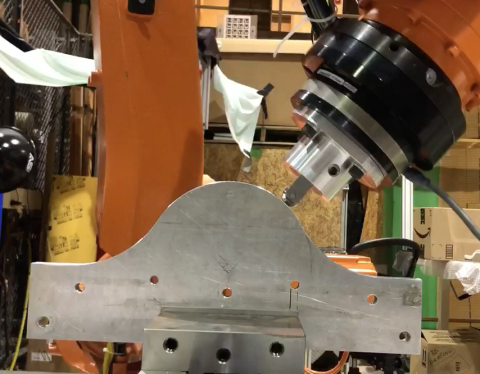

- Manufacturing: material handling, assembly, inspection

- Space: satellite servicing

- Assistive: handicapped or elderly care.

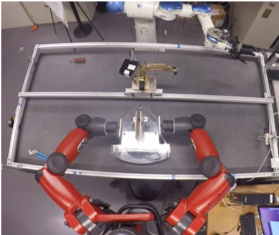

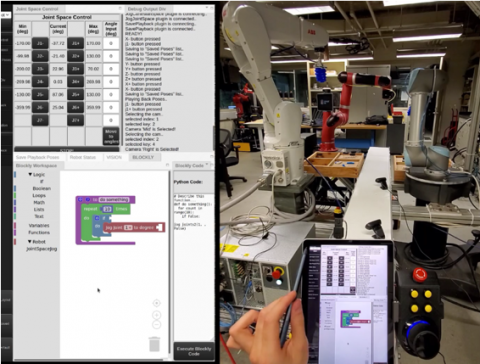

We integrate various sensors, end effectors, and input devices with industrial robots to make them more easily programmable and able to perform sensor based operations. We utilize outer (kinematic loop) control together with optimization-based velocity resolution to achieve a wide range of functionalities (from visual servoing to compliant force control).